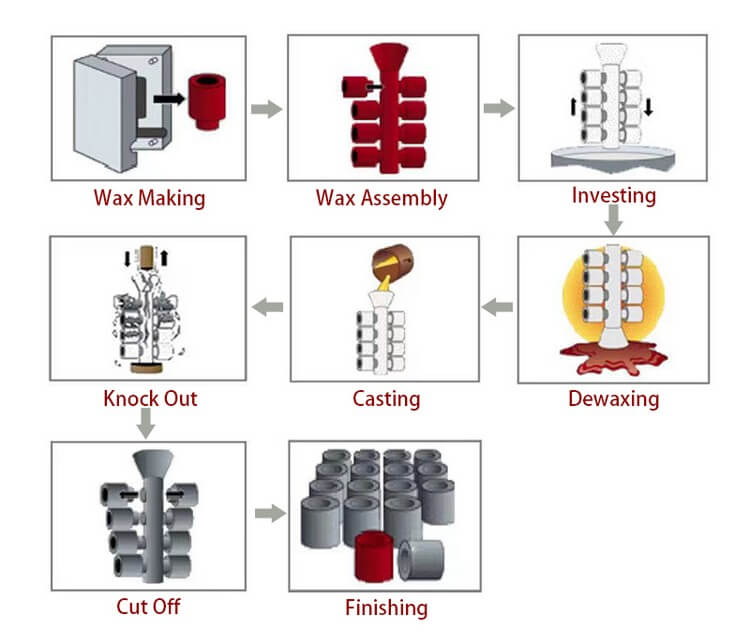

Wax Making

Wax replicas of the desired castings are produced by injection moulding using a metal die. These replicas are called “patterns”.

Wax Assembly

These patterns are attached via a “gate” to a central wax stick, referred to as a “tree” or “sprue”, to form a casting cluster or assembly, and mounted on a pouring cup.

Investing

A shell is built by immersing the assembly in a liquid ceramic slurry and then into a bed of extremely fine sand. Several layers may be applied in this manner.

Dewaxing

Once the ceramic is dry, the wax is melted out in an autoclave, creating a negative impression of the assembly within the shell. The shell mould is then fired in a high temperature oven.

Casting

The shell is filled with molten metal using various techniques and, as the metal cools, the parts, gates, tree and pouring cup become a solid casting.

Knock out

When the metal has cooled and solidified, the ceramic shell is broken off by vibration or water blasting.

Cut off

The parts are cut away from the central tree using a high speed friction saw.

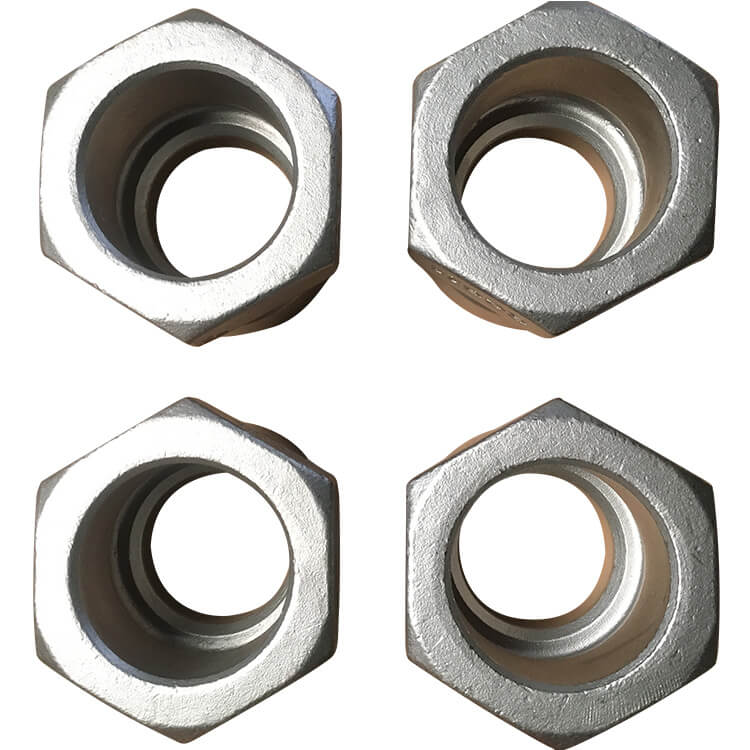

Finishing

Minor finishing operations, such as fettling and grinding, are undertaken to produce a metal casting identical to the original wax pattern.