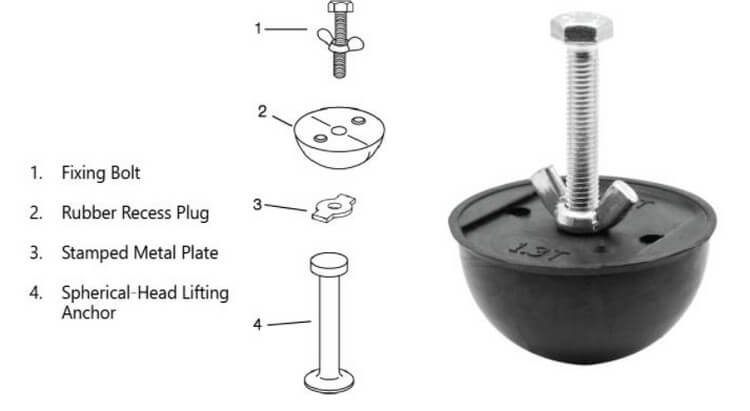

Rubber Recess Former are used to accurately create the correct recess to accommodate the Locking claws during casting, the Rubber Recess Former is moulded from a rubber compound exclusively developed to ensure longevity when in contact with concrete. Solid metal formers have a thread fitted in the back to fix to the mould. The outer curved surface of the rubber compound has a hole at its apex to allow the anchor to extend out of the rubber recess former. It is made of highly durable rubber encasing a high tensile steel bolt, complying with many international standards.

The key benefits and features for Rubber Recess Former are as per below:

• Hard oil resistant, yet flexible, rubber

• For attachment to steel and timber forms or floats

• Durable rubber case allows easy and clean removal

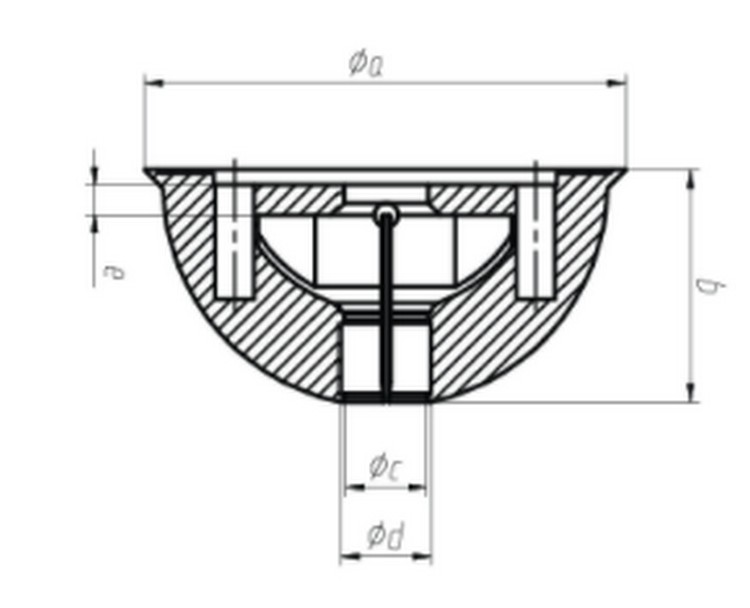

| Dimensions(mm) | |||||||

| S.W.L | a | b | b | d | e | f | g |

| 1.3T | 66 | 32 | 9.5 | 10.5 | 6.5 | 38 | 6.5 |

| 2.5T | 80 | 38.7 | 13.5 | 15 | 7.5 | 50 | 6.5 |

| 5.0T | 100 | 46.5 | 19.5 | 21.5 | 8.5 | 60 | 8.5 |

| 10T | 128 | 60.7 | 27.5 | 29.5 | 9 | 80 | 10 |

| 15T | 170 | 80 | 38 | 35.5 | 8 | 110 | 12 |

| 20T | 170 | 80 | 38 | 39.5 | 8 | 110 | 12 |

| 32T | 236 | 107 | 50 | 52 | 13 | 110 | 12 |

Application: It is applied to buildings and matched with appropriate lifting clutch and rubber recess former according to the model.

Rubber Recess former is used to accurately and reliably set the anchor into its recess in the concrete panel. The Rubber Recess Former can receive all our anchors in load groups of 2.5 t, 5.0 t, 7.5T and 10.0 t.

After-Sales: Provide Installation document